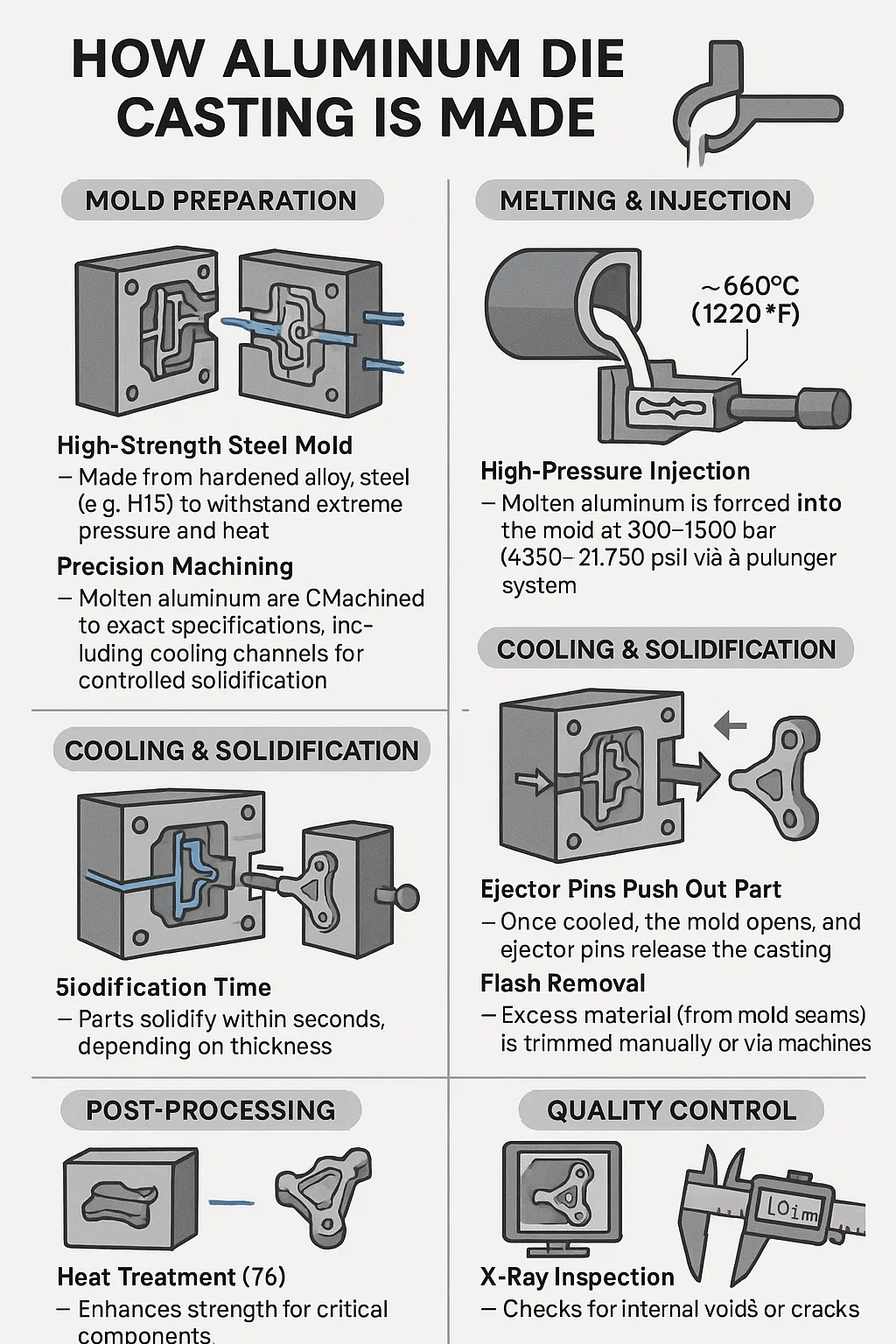

Quam Aluminium mori mittentem factum

I.

High-fortitudinem ferro Finge - fecit a induratum Alloy Steel (E.G .: H13) ad resistere extremam pressura et æstus.

Precision machining - Fingunt Cavitates sunt CNC, machined ad exigere cubits, comprehendo refrigerationem channels ad imperium solidificatione.

II. & Liquescens iniectio

Aluminium Alloy Alloy - Special Alloys (velut A380 et AdC1) sunt liquefacta ad ~ DCLX ° C (MCCXX ° F) in fornace.

High-pressura iniectio - Aluminium est coactus in FORMA at 300-1500 Bar (4350-21,750 Psi) Via a plunger ratio.

III. Refrigerationem & solidificatione

Celeri frigefaciendo - et fingunt in aqua channels ensure uniformis refrigerationem, ne warping.

Solidification tempus - partes solidatur in seconds, fretus crassitudine.

IV. Eiectio & TONDING

Picis ejector excludit ex parte - olim refrigeratum, et fingunt opens, et ejector paxilli dimittere proiectio.

Flash remotionem - excess material (ex fingunt summe) est ornata manually aut per machinis.

V. Post-processus

Calor Treatment (T6) - Enhances vires ad discrimine components.

Superficies finitionis - Sandblasting, politicos, aut Anodizing ad corrosio resistentia.

VI. Qualitas imperium

X-Ray inspectionem - checks pro interno evacuat vel rimas.

Dimensional Testing - ensures partes occursum stricta tolerances (± 0.1mm).

Key provocationes & Fixes

| Exitus | Facio | Solution |

| Poratus | Capti Air / Gas | Vacuum, adiuvit casting |

| ADMITTATIO | Impare frigefaciendo | Optimized fingunt refrigerationem channels |

| Haerens | Aluminium vincula ad fingunt | Advanced FORM coatings (E.G., stannum) |